Siemens annouced cooperation to realize visual computing platform for immersive experiences

June 15th, 2021 Darmstadt, Germany

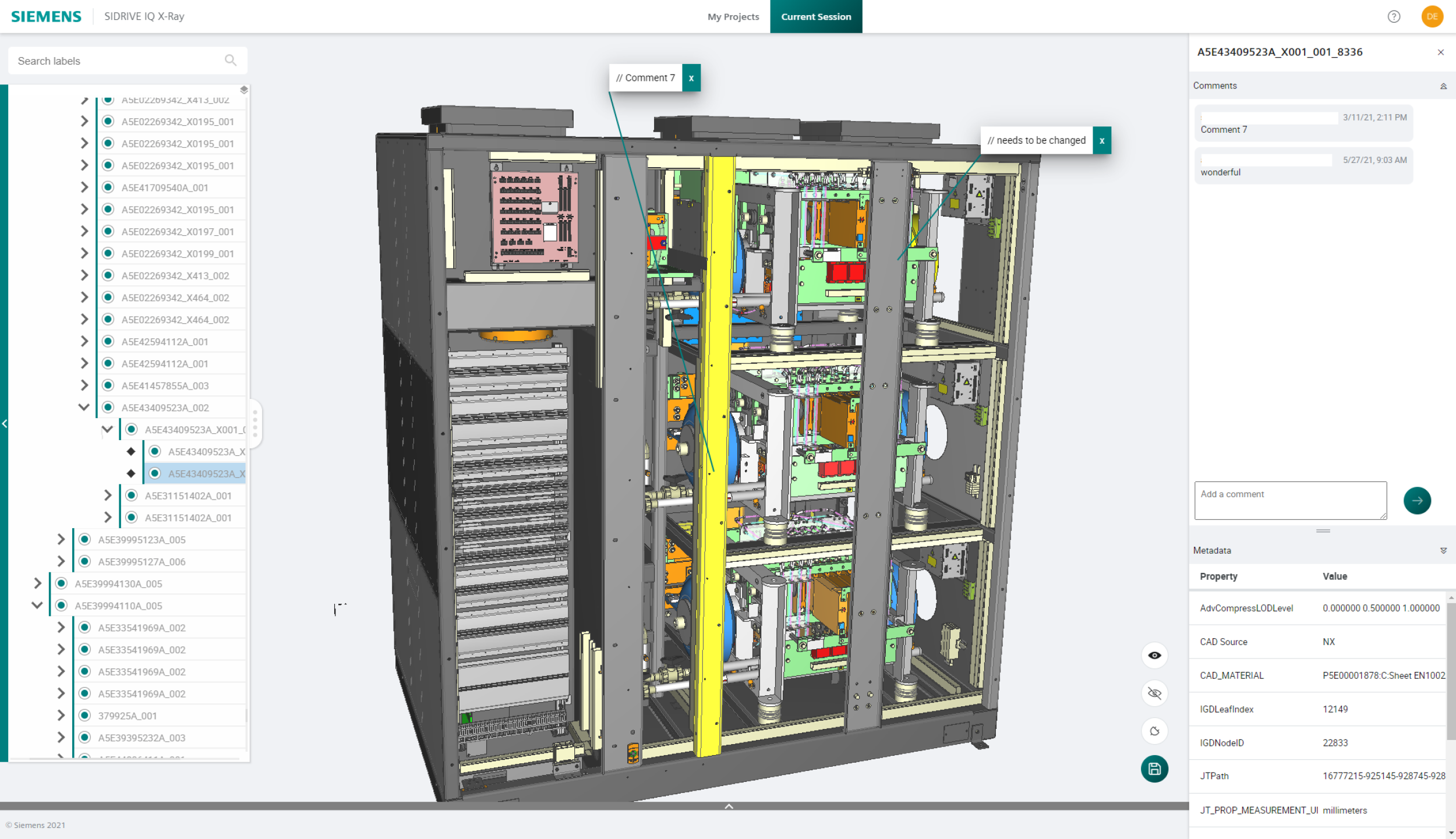

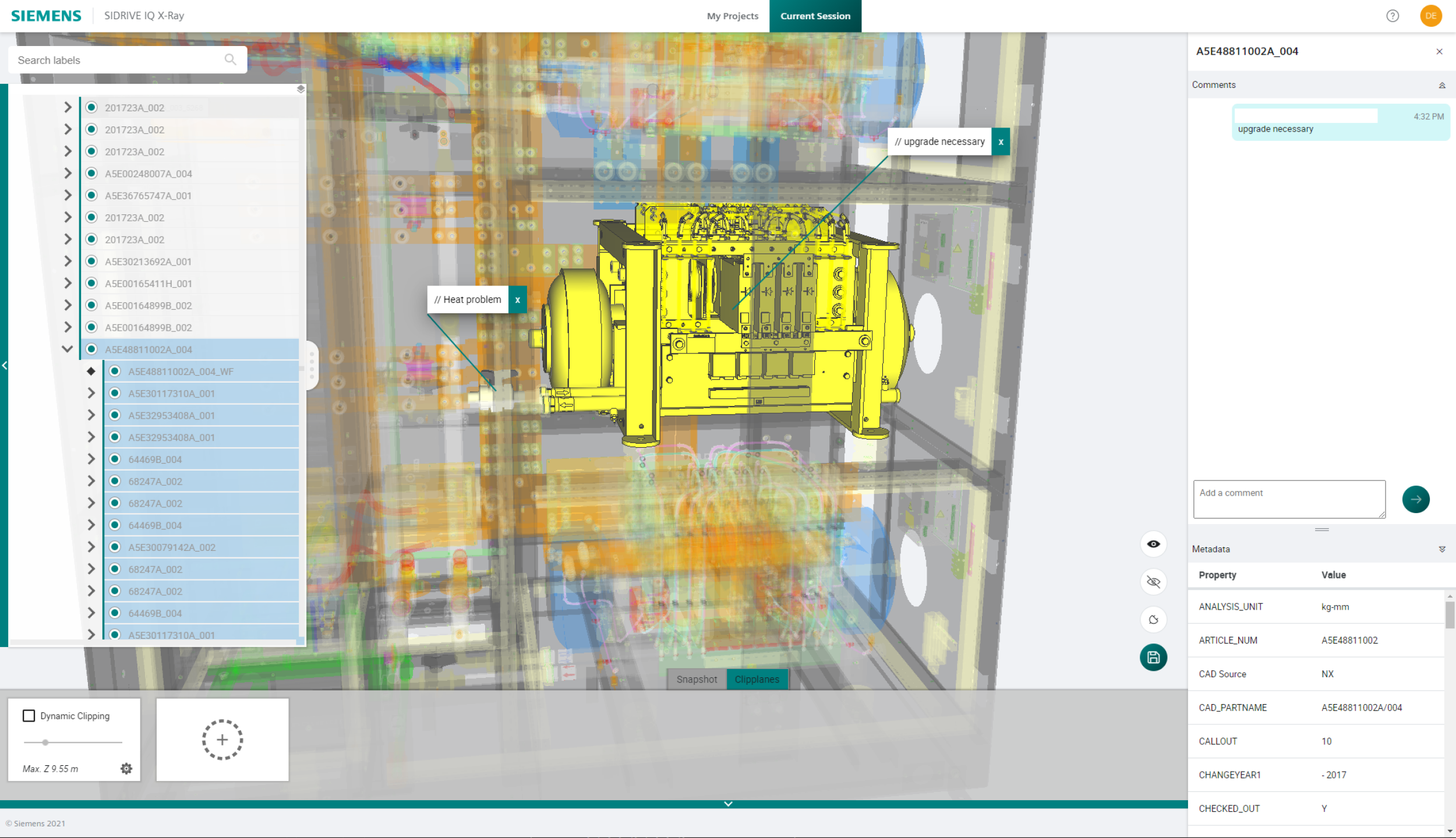

The new solution allows to unlock digital model data along the product lifecycle for drive systems. Accessing CAD data in web, Augmented Reality and Virtual Reality instantly. Combine IIoT with visual computing for design collaboration and troubleshooting

Bringing 3D Data into an existing Digital Twin Platform

Drive systems are core assets in industrial processes. Key aspects of the structural design and functionality are reflected in digital twins. Visualizing digital model data along the product lifecycle of a drive system is key in operational tasks from collaboration in design to remote service or troubleshooting. Moreover, the introduction of augmented reality and virtual reality in the industrial domain yields the potential to become a productivity driver for the human interaction with data.

The cooperation of Threedy and Siemens enriches Sidrive IQ - the digital platform for drive system & solutions of Siemens - with the decades of know-how converged in Threedy’s visual computing platform instant3Dhub. Integrating a range of functionalities into one seamless solution, Sidrive IQ will combine IIoT and 3D data resulting in digital content that empowers customers to understand drive systems better and resolve faults more efficiently

Scalable 3D and XR applications with instant3Dhub and Sidrive IQ

“We are progressively adding features to our digital platform Sidrive IQ – and with this also to our drive systems, solutions and services. Combining immersive experiences with IIoT-capabilities is a critical differentiator for the human-machine interaction because to a large extend it is people who eventually interact and act with AI-based insights and digital content in daily business operations. The cooperation with Threedy further completes the ambition to serve a holistic and user-centric experience,” states Sebastian Winkler von Mohrenfels, Head of Digital Business of Large Drives Applications.

“3D and XR applications, especially collaborative ones, offer their maximum value when the 3D visualizations are integrated with live business data in a highly dynamic manner. The cooperation with Siemens, and particularly the integration of instant3Dhub into Sidrive IQ, offers exactly this, as part of a state-of-the-art IIoT solution”, added by Christian Stein, CEO Threedy GmbH.

Terms